Safety Program:

Employee is to print and sign the following document upon

having read this Handbook.

![]()

General Statement of Safety Policy:

SOLANO’S INC. and its management team

have a responsibility to provide all reasonable safeguards for

employee health and safety in compliance with Federal and State

laws/regulations. We also have a responsibility to direct and

insure that employees perform their assigned tasks in a safe working

manner. Most of all, we have a responsibility to develop a

safety awareness in our staff.

Providing a safe and healthy work

environment is a business objective as well as a moral one.

Injury and illness represent lower productivity, staffing issues,

higher insurance costs, potential fines and litigation. An

accident free workplace is good for business as well as employees.

Our Injury/Illness Prevention Program:

SOLANO’S INC will continue to have an

effective Injury & Illness Prevention Program (IIP). Our

program includes creation of this updated IIP Program manual that

defines our safety program, requirements for training our staff

regarding safety procedures and work rules, scheduled inspections at

each of our facilities with follow-up corrective actions and

procedures for handling jobsite incidents. Details of each of

these elements will be discussed and expanded in following portions

of this manual.

The Injury and Illness Prevention Program

Manual consists of two parts, Part 1 describes the IIP program

policies and procedures and Part 2 provides detail work rules to be

followed to ensure safety in our workplace.

SOLANO’S management encourages all

employees to make suggestions for improvement in our working

environment and will continue to add to or revise this document when

improvements are recognized.

A safe and healthy working environment

requires active participation of the entire staff. For

purposes of this discussion, four discrete levels within the staff

are described and their general duties and responsibilities

identified.

Corporate

Management:

Corporate officers are ultimately responsible for providing a safe

environment for the conduct of the Corporation’s business

activities. The policies and procedures of the corporation

must comply with Federal and State laws and regulations, notably

Cal/OSHA, as to health and safety.

To assist them in their duties, they shall call upon various

corporate functions including Facility Managers, Human Resources,

Controller, Information Technology and an appointed member of the

organization referred to as the Safety Coordinator.

1)

Understanding the corporation’s responsibilities under

applicable Federal and State health and safety laws and regulations.

2)

Implementing an Injury and Illness Prevention program.

3)

Monitoring IIP program compliance.

Facility Management:

Each of SOLANO’S entities has a Facility (Store) Manager.

These individuals are key to the success of our IPP program.

They insure that employees assigned to their facility are performing

their assigned tasks in accordance with the procedures described in

the IIP program documentation.

Facility Management is responsible for:

1)

Assuring that the IIP program is presented to each member of

their staff.

2)

Reviewing actual job performance to assure compliance with the

policies and procedures defined in the IIP program documentation.

3)

Determining possible hazards in their facility and developing

acceptable alternatives to resolve hazard potential.

4)

Preparing documentation required to report accident/exposure

incidents.

5)

Assuring proper training of their staff.

Safety

Coordinator:

The Safety Coordinator has a number of responsibilities to assure

that the corporation’s daily activities are conducted in a safe

workplace environment. This position reports directly to the

CEO.

Safety Coordinator is responsible for:

1)

Awareness of changes in Federal and State workplace safety

regulations.

2)

Preparation of the Injury and Illness Prevention program

document.

3)

With the Facility Managers, perform periodic facility audits

for safety procedure and work rule compliance.

4)

Assist the Facility managers in resolving identified actual or

potential hazardous conditions.

5)

With the Facility Managers, review safety/illness incidents

and assure proper documentation and remedial actions as required.

6)

Providing reporting forms and documentation required as

defined in the IIP Program manual.

7)

Provide training aids, safety posters, documents and

specialist speakers as required.

Other Team

Members:

As stated, safety in the workplace is the

responsibility of all members of the corporation. Your actions

and observations are critical to achieving our goal of having an

accident free workplace environment.

Team Members are responsible for:

1)

Having a clear understanding of the IIP Program content,

procedures and objectives.

2)

Following safety/illness rules as defined in the IIP Program

documentation and/or as directed by their supervision.

3)

Reporting injury/illness incidents immediately to the

applicable Facility Manager or in his absence, the Safety

Coordinator or CEO.

4)

Reporting actual or possible hazardous conditions or behaviors

to their Facility Manager or the Safety Coordinator.

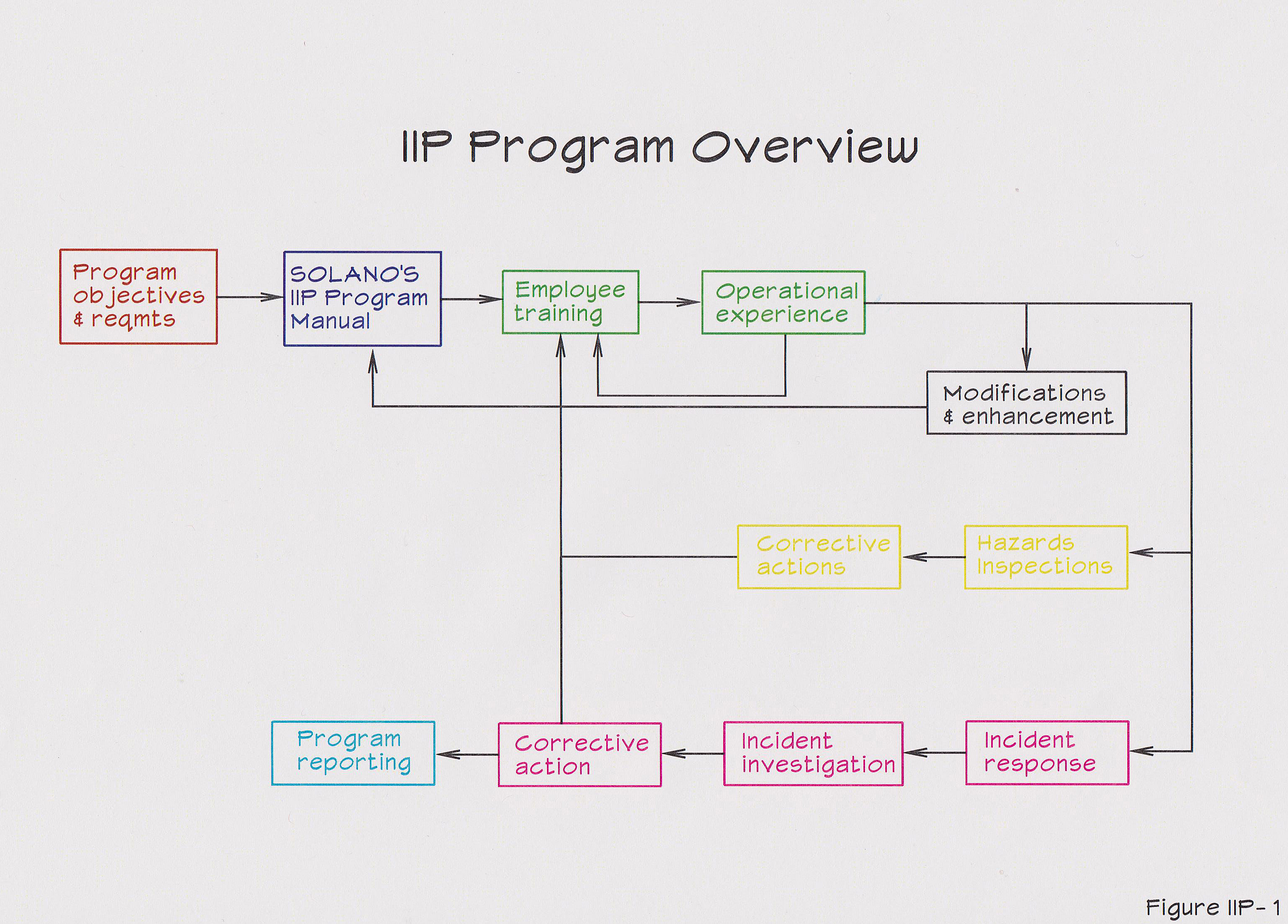

The following figure, IIP-1, illustrates the

significant activities that are involved in our safety program.

Descriptions of select blocks on the figure are provided below.

Program

Objectives:

Our IIP Program must comply with a number of

requirements defined by outside organizations as well as the goals

of SOLANO’S INC. The health and safety of our employees is of

interest to two Occupational Safety and Health Administrations,

Cal/OSHA and Fed/OSHA. These government entities administer

laws and regulations affecting the health and welfare of our

workers. Also, our Workers Compensation Insurance carrier and

State Division of Workers Compensation are involved in industrial

workplace incidents that result in workers claims. Last but

not least, our corporate management desires to provide the staff a

safe and healthy environment.

IIP

Program Manual:

Based on

the objectives and requirements, this Injury and Illness Program

Manual was created by our Safety Coordinator. As indicated on

the figure, modifications and/or enhancements to the manual will be

made as operating experience mandates.

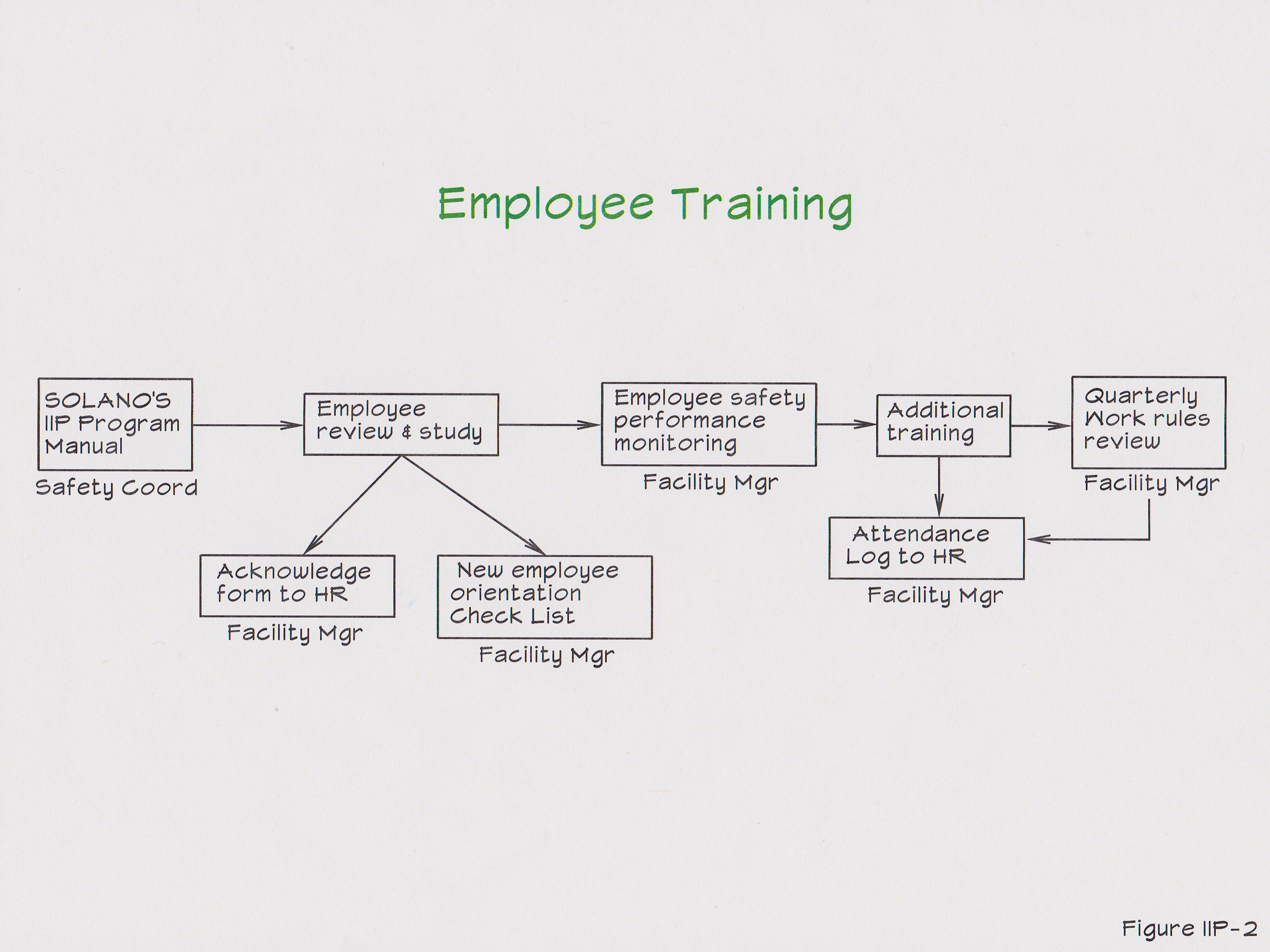

Employee Training:

As shown in Figure IIP-2, employees must review and

study the IIP Program Manual and acknowledge their understanding of

the procedures and work rules that apply to their location and work

assignments. New employees receive an Orientation presentation

from their Facility Manager that includes review of this manual.

See form EO-1, the Orientation Checklist.

Upon completion of becoming familiar with the content of the manual,

each employee shall sign and date the Employee Acknowledgement Form

(EA 1) and return it to the applicable Facility Manager for

forwarding to HR (Pam Hansen). The completed form becomes part

of the employee’s data file.

Facility Managers shall continually review their employee’s

compliance with the published procedures and work rules. If

remedial or changed work rule training is required, the Facility

Manager shall conduct such training with support of the Safety

Coordinator. An attendance log indicating the training

subject, date and names of those employees attending shall be

forwarded by the Facility Manager to HR. Quarterly, Facility

Managers shall schedule a meeting(s) with their staff to review the

work rules applicable to their facility.

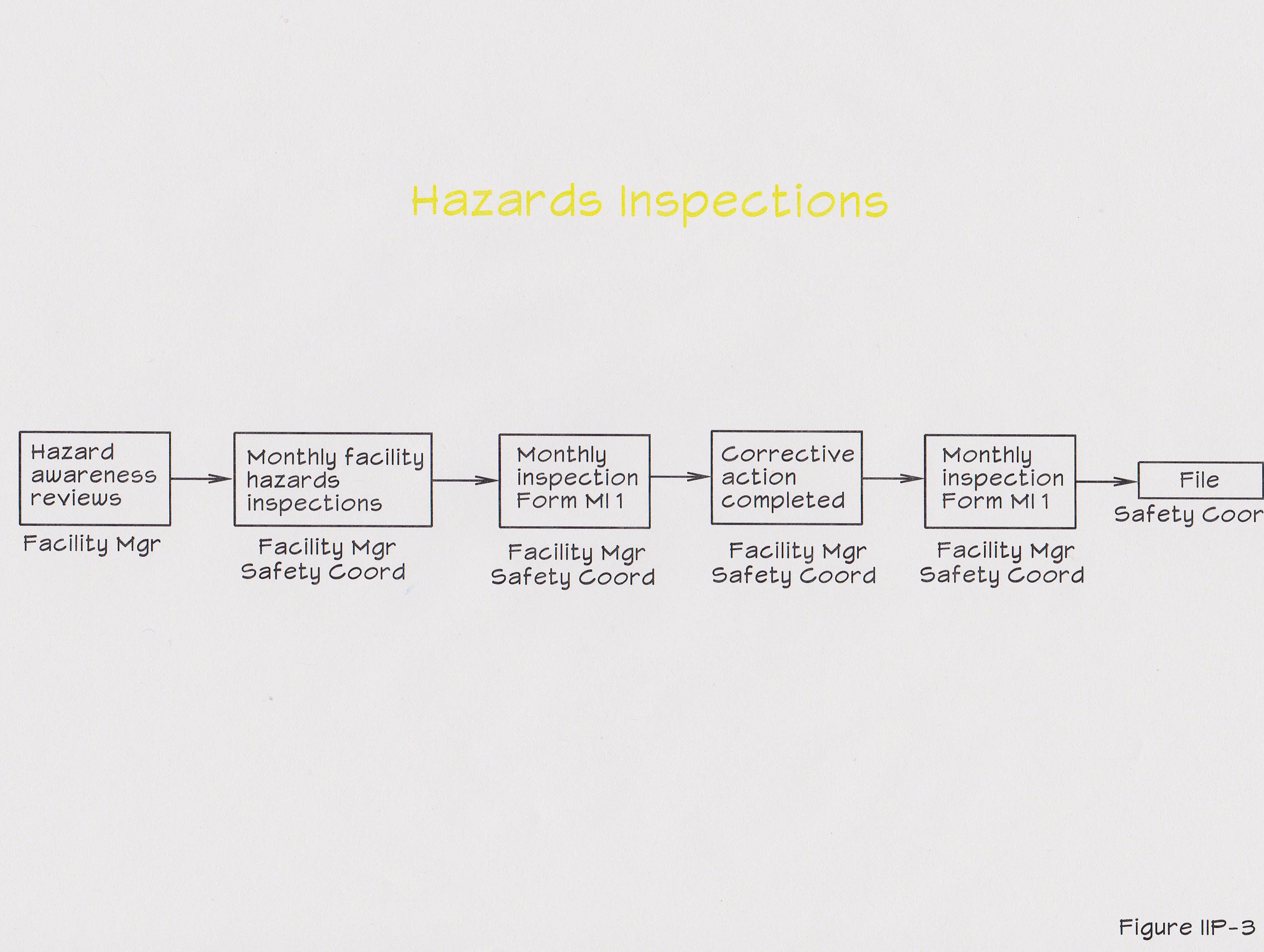

Hazards Inspections:

The Facility Manager shall on a daily basis, review his facility

status regarding safety issues and compliance with the published

procedures and work rules. As shown in Figure IIP-3, a monthly

walk through inspection of each facility is to be conducted by the

Facility Managers and the Safety Coordinator. The results of

the inspections are recorded on Form MI-1. Items requiring

corrective action are noted and the date corrections are made

entered. Upon completion, Form MI-1 is forwarded to the Safety

Coordinator by the Facility Manager for filing. If changes in

procedures or equipment/structures are recommended, the Facility

Manager shall contact the Safety Coordinator who will obtain

resolution of the issue by contact with the CEO.

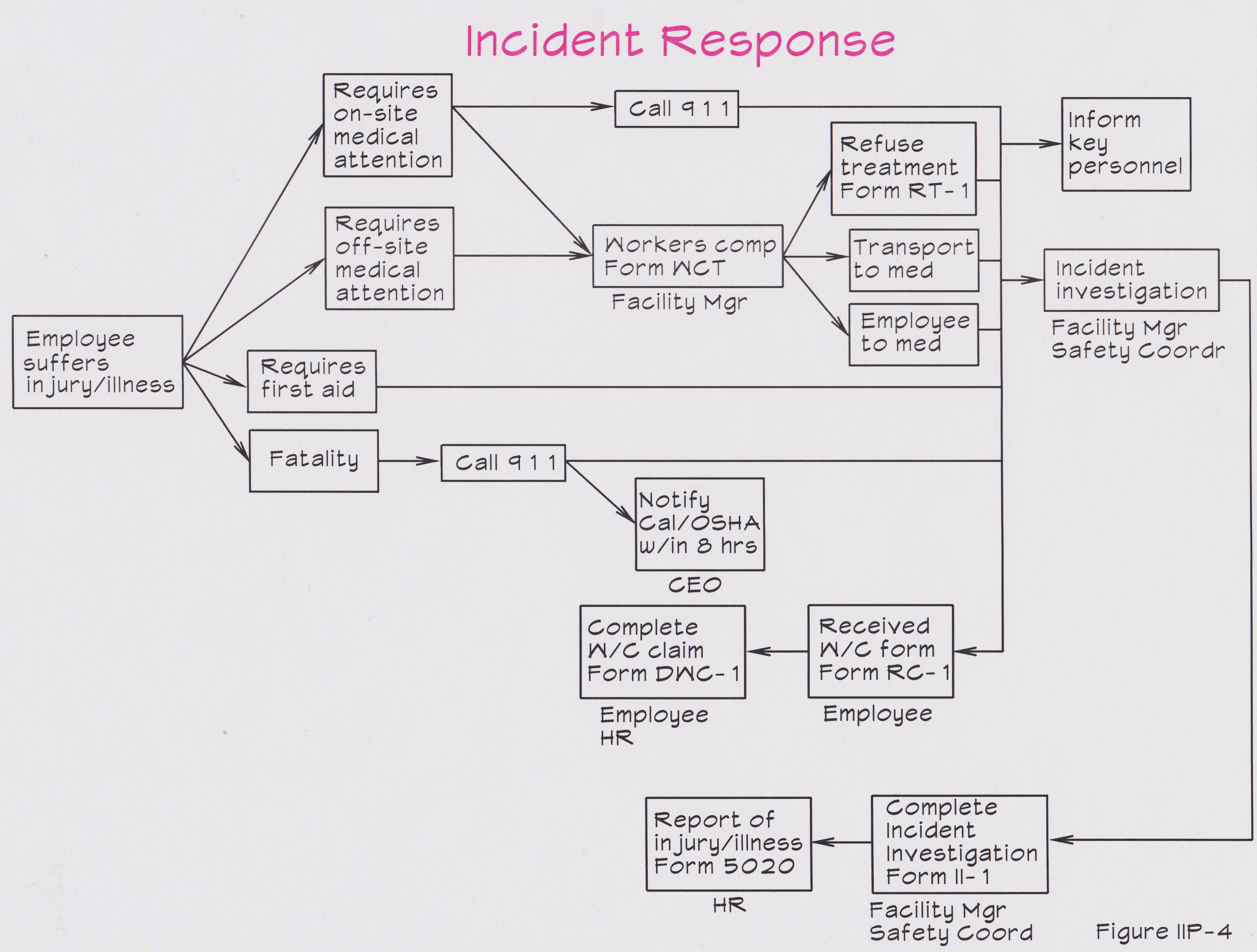

Incident Response:

Response to an employee injury involves numerous

actions and documents. Figure IIP-4 illustrates the major

steps involved. The simplest case is when the injury requires

only first aid performed at a SOLANO’S site or if the treatment by a

medical professional is classified as first aid. This option

does not require preparing a Worker’s Compensation treatment

referral document or Worker’s Comp claim form. See Figure II-5

for a description of First Aid.

The second case is where a professional medical person is required

to provide treatment beyond first aid. If the injury is so

severe that the employee is not mobile, ambulance or first

responders should be called via 911. If the employee is mobile

they should be offered treatment by a medical professional. If

they do not wish treatment they must complete Form RT-1, Refuse

Medical Treatment. They may choose to have treatment at a

later date. When treatment is chosen, Form WCT is to be

completed and copies provided to the employee to present to Dr. D.

Higer or Mercy Medical Center emergency room for treatment. If

the employee has filed an exception form with HR, they may be

treated by their elected medical service provider in lieu of Dr.

Higer or Mercy Medical Center. The employee may be provided

transportation or allowed to travel on their own depending on the

nature of the injury.

Injuries or illness that require treatment beyond first aid are

potential Worker’s Comp cases. The employee is to be provided

with the claim form, Form DWC 1 and they must sign Form RC-1

acknowledging that they have been provided with the claim form.

All employee injury or illness incidents including fatalities

require an incident investigation. The investigation is to be

performed by the applicable facility manager and the Safety

Coordinator. Results of this investigation are recorded on

Form II-1, Incident Investigation. Incidents that result in

lost time beyond the date of the incident or medical treatment

beyond first aid must be reported to Cal/OSHA on Form 5020 within 5

days of the incident occurrence. Fatalities must be reported

to Cal/OSHA by phone or fax within 8 hours of the incident.

Within 24

hours of an incident (not a fatality), the CEO, the Safety

Coordinator, and Human Resources must be informed by the applicable

Facility Manager or lead individual who attended to the injured.

First Aid Definition

As defined by Cal/OSHA

for incident reporting

·

Visiting a licensed health care professional sole for observation or

counseling.

·

Diagnostic procedures such as x-rays and blood tests or other

diagnostics (but not treatment).

·

Using a non-prescription medication at non-prescription strength.

·

Cleaning, flushing or soaking wounds on the skin surface.

· Using wound coverings such as bandages, Band Aids, gauze pads or butterfly bandages and Steri-strips. (No sutures or staples).

·

Using hot or cold therapy.

·

Using non ridged means of support such as elastic wraps.

·

Temporary immobilization devices while transporting a patient.

·

Draining fluid from a nail or blister.

·

Using eye patches.

·

Removing foreign bodies from the eye using only irrigation or cotton

swab.

·

Providing drinking fluids for relief of heat stress.

Figure II-5

Program

Reporting:

A number of forms have been described as we have

defined the IIP Program in effect at SOLANO’S INC. There are

two additional forms required by Cal/OSHA, Forms Cal/OSHA 300 and

300A. Form 300 is a log of work related incidents that result

in days away from work or medical treatment beyond first aid.

Enter number of days away from work when the employee returns to

work. Form 300A is an annual summary of lost time incidents is

prepared by the Safety Coordinator and must be signed by the CEO and

posted in SOLANO’S facilities by February 1 of each year.

Employee Behavior:

SOLANO’S INC. reserves the right to

discipline employees who knowingly violate company safety rules or

policies. Disciplinary measures will include but not be

limited to:

-

Verbal warning for minor offenses.

-

Written warning for more severe or repeated violations.

-

Suspension without pay, if verbal and written warnings do not prove

sufficient.

-

Finally, if none of the above measures prove satisfactory, and no

other acceptable solution can be found, the company will have no

choice but to terminate employment for those who

continue to jeopardize their own safety, and the safety of others.

FORMS

Note: Forms included in this section are for illustrative

purposes and are not to be removed or copied for use. Contact

your Manager or the Business Office for forms to be used for an

incident.

Monthly Hazards Inspection

MI-1![]()

Workers Comp Treatment Referral

WCT![]()

Cal/OSHA Injury or Illness Report

Form 5020![]()

Cal/OSHA Log of work related

injuries/illnesses Form 300![]()

Cal/OSHA Annual summary

Form 300A![]()

This portion of our II Program Manual

presents specific instructions that pertain to operations at the

various SOLANO’S facilities. Wherein Part 1 described the

safety program content, procedures and Corporate policy, Part 2

presents detail information on how to perform your work tasks

safely.

Personal Responsibility:

We can have the best Safety Manual in the industry, but if we

employees don’t have Safety

on our minds, we will not have a safe working environment. The

following list highlights personal behavior traits that help create

and maintain an injury free working environment.

1) Be

alert to unsafe work methods or unsafe conditions. Correct them or

report them to your supervisor immediately. Don’t wait for an

accident to happen.

2)

Report every injury immediately, serious

(your judgment) or not.

3)

Reporting to work under the influence of

alcohol, narcotics or other substances can affect your

performance, endangering yourself and others.

4)

Horseplay and/or practical jokes can

cause accidents.

5)

Obey smoking rules (designated areas

only).

6)

Keep your work environment clean and in

order.

7)

Be aware of your footing conditions.

Watch your step.

8)

Clean up spills at once.

9)

Keep aisles clear. Material stacked

safely.

10) Wear

proper clothing and footwear.

11) Walk,

don’t run. Better to be slow and safe than fast and dangerous! This

includes forklift operation.

12) Follow

the work rules presented in this manual.

Fall Prevention

The number one construction industry

injury accident is from falling. Because of the frequency of

these accidents, Cal/OSHA has created strict rules for working at

heights. Workers operating more than six foot above a

ridged surface, IE earth or floor, must be protected one of three

ways:

42” guard rails around the work platform (scaffolding, balcony or

man lift)

A personal protection harness and lanyard device

An approved safety net

SOLANO’S personnel are not allowed to operate on roof surfaces of any height. If they are required to perform activities within our facilities above the 6 foot limit they must comply with the following:

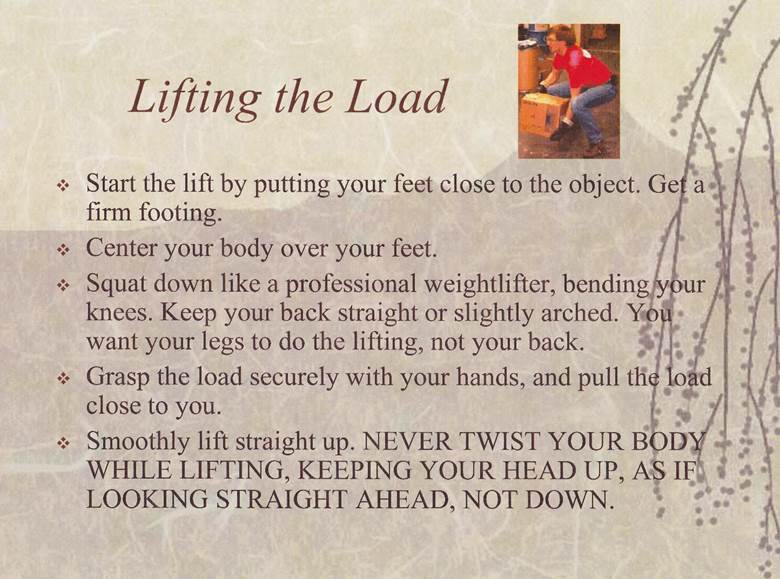

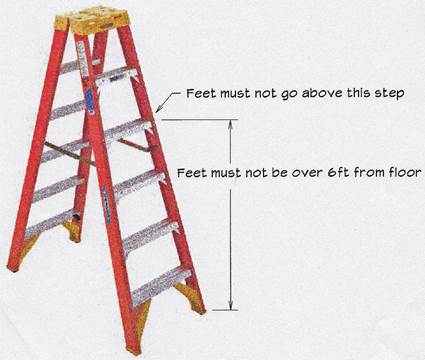

Use of step ladders is limited to one

option. A step ladder may be used if the worker’s feet are no

more than 6 feet from the floor and are no higher than the second

step from the top of the ladder as shown on the following

illustration.

In all cases, the ladder horizontal

braces shall be locked and the feet of the ladder placed on a

secure, level surface. Step ladders shall not be used when

closed, leaning against a wall or other support. The

horizontal members on the back side of the ladder must not be used

as steps.

WRONG!

Temporary employees may have more limiting

requirements regarding work above floor level. Confirm

requirements before scheduling or performing tasks.

Heatstroke

Prevention

Heatstroke

Prevention

Awareness of heat illness symptoms can

save your life or the life of a co-worker.

When working in the heat be sure to pay

extra attention to how you and your co-workers are functioning and

be sure you know how to call for medical attention if required.

Drinking plenty of water is vital.

An individual exposed to excessive heat can produce as much as two

gallons of sweat per day. To replenish that fluid, a worker

should drink 3 to 4 cups of water every hour starting at the

beginning of your shift. Caffeine drinks are to be avoided.

If you feel flushed but are not sweating

you may be approaching a serious condition. If you start to

feel symptoms such as nausea, dizziness, unusual fatigue, stop

working and rest in a cool shaded area. If symptoms persist or

worsen seek immediate medical attention.

Under excessively hot conditions, take

frequent breaks in a cooler shaded location to allow for heat stress

recovery.

The driver assigned to a delivery truck is responsible for

stocking the truck with the daily drinking water supply.

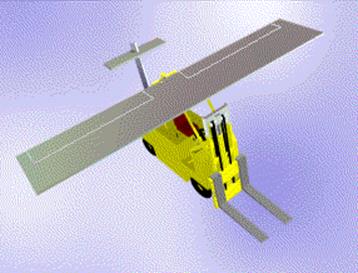

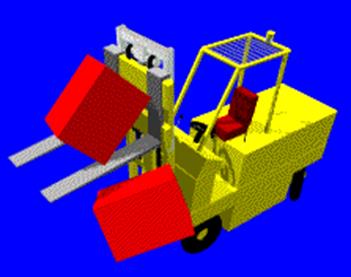

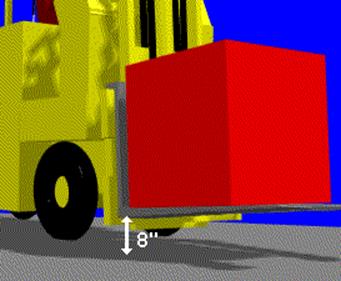

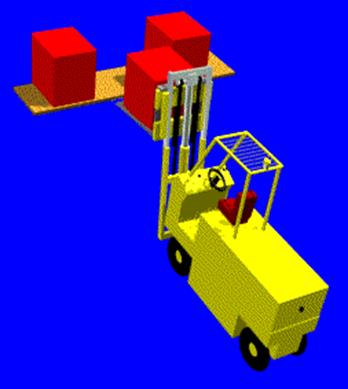

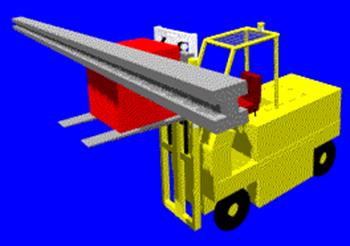

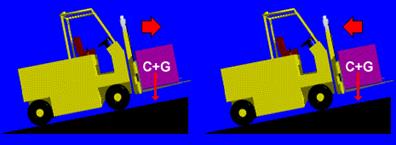

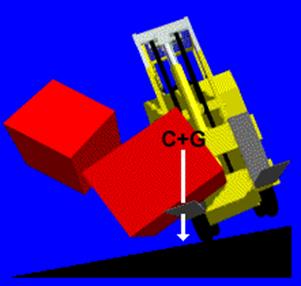

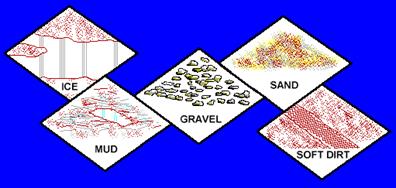

Forklift Operation

Operation of forklifts is not allowed

until the employee has completed training and observation/testing

provided by the Yard Supervisor or

Facility Manager. The following illustrations are provided as

a reminder of rules for safe forklift operation.

Keep in mind you are

operating a forklift, not a race car or a jet fighter. In case

of an accident, you don’t have an ejection seat. Always start and

stop smoothly, and keep your speed down.

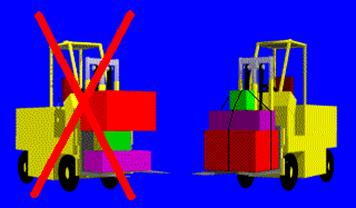

The higher you lift the load,

the more unstable it becomes. Always take extra care when

making sharp turns with a raised load.

If a load blocks your view,

travel in reverse.

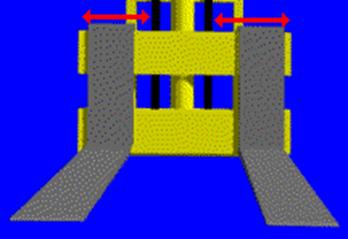

Take time to adjust the forks to

fit the load you will be carrying. Adjusting forks outward for

wide loads helps you to center the load, and makes it more stable.

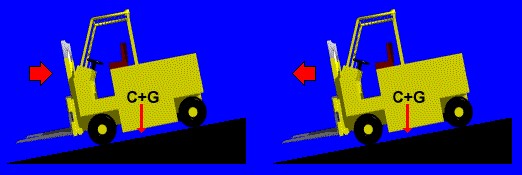

If driving an empty forklift, travel in reverse up an incline and forward down an incline. Note that the center of gravity for the forklift is above the front wheels under both conditions.

If driving a loaded forklift, travel forward up an incline and backward down the incline. Note that the center of gravity for the forklift is above the front wheels under both conditions.

![]() .

This material shall be read by the employee before the

observation/training is conducted by the supervisor.

.

This material shall be read by the employee before the

observation/training is conducted by the supervisor.

![]() for fossil fueled lifts and

for fossil fueled lifts and

![]() for battery powered equipment. A copy of the applicable form

is to be printed, completed and signed by the operator and the

evaluator/trainer.

for battery powered equipment. A copy of the applicable form

is to be printed, completed and signed by the operator and the

evaluator/trainer.

Several of our facilities have Miter

(Chop) saws provided to cut custom lengths of moldings, trim etc.

Operated improperly these tools can cause serious injury.

Employees utilizing these in the course of their daily duties shall

review the following material before using the equipment. A

form is provided at the end of this material which shall be signed

by the employee and forwarded to HR for filing in their personnel

folder. If you have any questions regarding use of these tools

contact your manager for clarification.

Safe operation includes the following

practices:

1)

Wear eye protection when operating a

miter saw.

2)

Do not wear gloves, loose clothing, or

jewelry that could become entangled in the saw.

3)

At least once a week the saw blade should

be checked to confirm it is sharp, has no broken or missing teeth

and is properly fixed to the drive shaft. The power cord must

be removed from the outlet during this inspection.

4)

The safety blade covering shield must

function properly. Check before using the saw.

5)

When cutting a board, it must be held

securely against the back fence. Normally use your left hand

to hold the material, placing your hand no closer than 6” to the

path of the blade. Use your right hand to lower the saw and

operate the power switch. Never cross your left hand over to

hold the material on the right side of the blade’s path. Short

pieces of material must be secured with clamps if they would require

placing your hand closer than 6” from the blade.

6)

Turn the saw on with the blade up and

allow the saw to come up to speed before lowering the blade into the

material to be cut. If you are using a sliding saw, start the

cut at the edge of the material closest to you and move the saw

through the width of the material.

7)

When cutting is complete, release the

power switch but hold the saw down until the blade has stopped

turning.

8)

If cutting long lengths of material be

sure it is properly supported so that it does not drop and bind the

saw or pull your hand into the blade.

9)

Do not attempt to rip saw (cut parallel

to the grain).

Press

![]() to print an acknowledgement form, sign and forward to HR.

to print an acknowledgement form, sign and forward to HR.

Chainsaw Operation

Several of our facilities have Chain

saws provided to cut custom lengths of timbers, BCI's etc.

Operated improperly these tools can cause serious injury.

Employees utilizing these in the course of their daily duties shall

review the following material before using the equipment. A

form is provided at the end of this material which shall be signed

by the employee and forwarded to HR for filing in their personnel

folder. If you have any questions regarding use of these tools

contact your manager for clarification.

Press

![]() to print an acknowledgement form, sign and forward to HR.

to print an acknowledgement form, sign and forward to HR.

Dispensing Propane

Solano's dispenses propane fuel at the

Rental Center and Contractor Building Supply locations.

Propane is a volatile liquid/gas and must be handled in a safe

manner to prevent damage to facilities and/or injury to personnel.

Mike Bedzyk is the corporate trainer for handling of propane

containers and dispensing equipment. New employees who may be

required to dispense propane (for customers or Solano equipment use)

shall be provided suitable training by Mike before performing

dispensing activities. All applicable employees shall be given

refresher training every two years. Upon completion of

initial or refresher training employees are to sign the applicable

acknowledgement form and forward it to HR.

The following sections should be

viewed by all trainees:

#1 Introduction

#2 Propane Properties

#3 Dispensing Equipment

#4 DOT Cylinders

#5 Small Cylinders

#6 Forklift Cylinders

#7 Motorhomes/RVs

![]() .

.

Press

![]() to print an acknowledgement form, sign and forward to HR.

to print an acknowledgement form, sign and forward to HR.

https://fs23.formsite.com/BlueStarGas/form121/index.html

https://fs23.formsite.com/BlueStarGas/form121/index.html